In the aerospace industry, where reliability, performance, and safety are paramount, the printed circuit board (PCB) plays an indispensable role. Aerospace PCBs form the backbone of electronic systems in aircraft, satellites, and space exploration vehicles, integrating and interconnecting various electronic components. This article explores the critical role of PCBs in aerospace applications, highlighting their unique requirements, advancements, and future prospects.

The Importance of PCBs in Aerospace

- Complex Systems Integration: Aerospace systems are highly complex, comprising numerous sensors, communication devices, and control systems. PCBs provide a reliable platform for integrating these components, facilitating seamless communication and functionality.

- Reliability and Safety: Aerospace missions, especially those involving space, demand the highest levels of reliability. PCBs must withstand extreme conditions and continue functioning flawlessly, ensuring mission success and crew safety.

- Size and Weight Constraints: Aerospace applications often face stringent size and weight limitations. PCBs are designed to maximize functionality while minimizing space and weight, crucial for optimizing the performance and efficiency of aircraft and spacecraft.

Unique Requirements for Aerospace PCBs

- Temperature Extremes: Aerospace environments can experience significant temperature variations, from the freezing cold of high altitudes to the intense heat of rocket propulsion. Aerospace PCBs must be designed with materials and coatings that can endure these extremes without compromising performance.

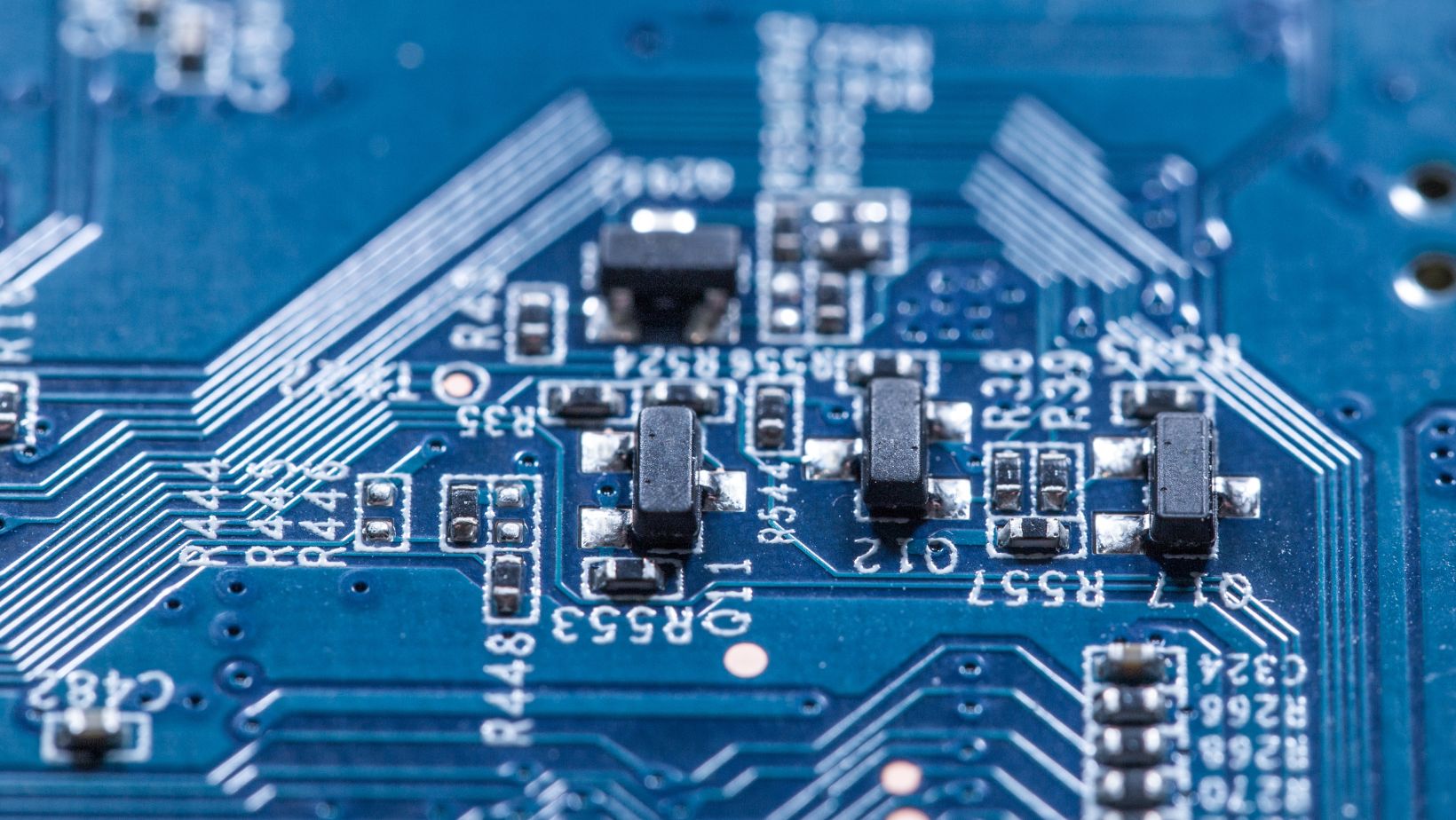

- Vibration and Shock Resistance: Aircraft and spacecraft endure substantial vibrations and shocks during operation. Aerospace PCBs are built to resist mechanical stresses, using robust materials and design techniques to prevent failure in these harsh conditions.

- Radiation Protection: Space missions expose PCBs to higher levels of radiation, which can damage electronic components and affect performance. Specialized shielding and radiation-hardened materials are used to protect PCBs from radiation-induced failures.

- Reliability and Longevity: The reliability of aerospace PCBs is critical, as failures can lead to catastrophic outcomes. High-quality manufacturing processes, rigorous testing, and quality control measures are employed to ensure long-term reliability and performance.

Advancements in Aerospace PCB Technology

- High-Density Interconnect (HDI) PCBs: HDI PCBs allow for higher circuit density and greater functionality within a smaller footprint. This advancement is particularly beneficial for aerospace applications, where space is at a premium.

- Advanced Materials: The use of advanced materials such as ceramic substrates and high-performance laminates improves thermal management, mechanical stability, and radiation resistance. These materials enhance the overall performance of aerospace PCBs.

- Flexible and Rigid-Flex PCBs: Flex Rigid PCBs combinations are increasingly used in aerospace applications to accommodate complex geometries and reduce weight. These designs enable more versatile and efficient use of available space.

- Thermal Management Solutions: Effective thermal management is crucial for maintaining PCB performance in extreme temperatures. Techniques such as heat sinks, thermal vias, and advanced cooling materials are integrated into the PCB design to manage heat dissipation.

- Automated Testing and Quality Assurance: Advances in automated testing and inspection technologies ensure that aerospace PCBs meet the highest standards of quality and reliability. These technologies facilitate comprehensive testing of PCBs under simulated operational conditions.

Future Directions and Challenges

- Miniaturization and Integration: The trend toward miniaturization continues, with the demand for smaller, more integrated PCBs that can deliver enhanced performance while occupying less space. This trend is driven by the need for more compact and efficient aerospace systems.

- Sustainability: The aerospace industry is increasingly focusing on sustainability, including the development of eco-friendly PCB materials and processes. Research into recyclable materials and reduced environmental impact is gaining momentum.

- Emerging Technologies: The integration of emerging technologies such as advanced sensors, artificial intelligence, and autonomous systems into aerospace applications presents new challenges and opportunities for PCB design and manufacturing.

- Enhanced Radiation Shielding: With the growing exploration of deep space, the need for advanced radiation shielding in PCBs is becoming more critical. Research into new materials and shielding techniques will play a vital role in future space missions.

Printed circuit boards are fundamental to the functionality and success of aerospace systems, providing essential support for a wide range of electronic components and systems. As the aerospace industry continues to advance, the role of PCBs will evolve, driven by the need for greater reliability, performance, and efficiency. Innovations in materials, design, and manufacturing processes will ensure that PCBs continue to meet the rigorous demands of aerospace applications, supporting the next generation of aircraft and space exploration technologies.